I am final year student who studying Offshore Engineering in Newcastle University. This is my third year living in Newcastle.

I am writing in here is because I want to create a place keep all these valuable experiences and memories I had during this three years’ time and share them with people who also have passion in offshore engineering.

Today, I want to talk about my final year project. To start talking about my project, is best to start with the KTP project which is Knowledge Transfer Project. It is a UK government funded project for knowledge transfer between university and industry which aim to improve the business from the knowledge based fundamental theory which provide from the university. In the other hand, though this project, the university can have deeper understanding on what the industry need and what are the technical problems facing currently, and hopefully improve existing method, come out with a more time and cost effective solution.

So, my project is collaborate with SMD Ltd. which is a ROV (remote operated vehicle) manufacturing company based in Newcastle. Welcome to visit SMD website: https://smd.co.uk/

I had contributed to meetings with SMD Ltd. and understand the problems involved in ROV operations and the engineering analysis. It is an honor to be part of this project. Thank you so much to SMD Ltd and Newcastle University for this opportunity.

PS: Saw a FPSO and a small barge outside SMD office.

PS: Saw a FPSO and a small barge outside SMD office.

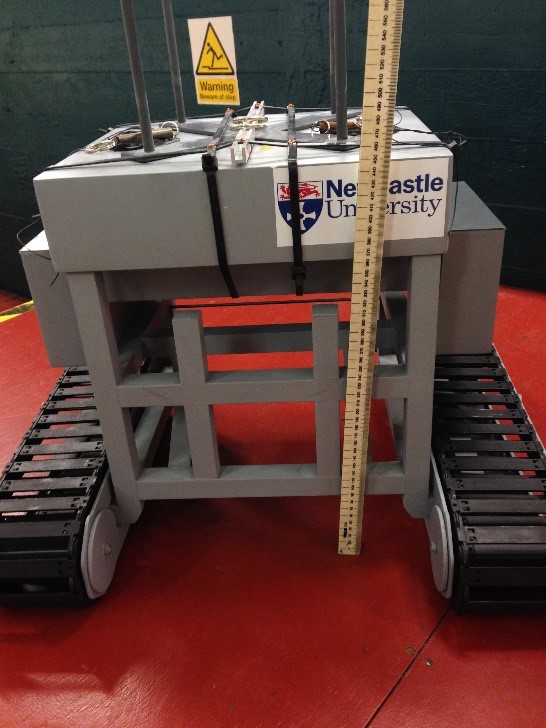

My final year project is title with Hydrodynamics Load on ROV during Recovery. Basically, it is to have deeper understanding on the ROV behavior during launch and recovery, including its motion and the hydrodynamic load. We have a Q-Trencher 1400 Model in the lab which have a scale of 1:12.

As part of my project, I designed a launch and recovery test system in the Newcastle University towing tank. I used about 4 weeks’ time to communicate with the lab technicians and my supervisor to find a winch motor which capable to give the ROV lift in two different constant speed. I also provided simple experiment set up drawings using AutoCAD to help the lab technicians. Finally, we conducted the tests in 16th March – 20th March. I am very happy because the results we got were expected.

As part of my project, I designed a launch and recovery test system in the Newcastle University towing tank. I used about 4 weeks’ time to communicate with the lab technicians and my supervisor to find a winch motor which capable to give the ROV lift in two different constant speed. I also provided simple experiment set up drawings using AutoCAD to help the lab technicians. Finally, we conducted the tests in 16th March – 20th March. I am very happy because the results we got were expected.

Alongside with the experiment testings, I also recorded and made a short video to summarize the work we did in a week in the lab. I was working for this video until 2.30am on Thursday night. That is because in case of any missing/failure screen, I will still have the opportunity to recapture the screen on Friday. Even thought it was a busy and tired week, but it worth me doing that anyway. I got many positive feedback from the lab technicians, from my supervisor, from my friends and family. And finally I am very happy to see everyone happy. =)

I believe this video will benefit to my university and also to SMD Ltd., not just the engineering knowledge but also the marketing part.

Thank you for reading, feel free to comment on the video, much appreciated to have your feedback. =)

Video: https://www.youtube.com/watch?v=IjD5ez0B1Po

Follow me on other networking websites:

YouTube: https://www.youtube.com/user/clandiasim

Linkedin: https://www.linkedin.com/in/clandiasim

Google+: https://www.google.com/+clandiasim

Slideshare: http://www.slideshare.net/ClandiaSim

Visit my personal blog as well! More stuff in there. =)

http://offshoreengineeronlive.blogspot.co.uk/