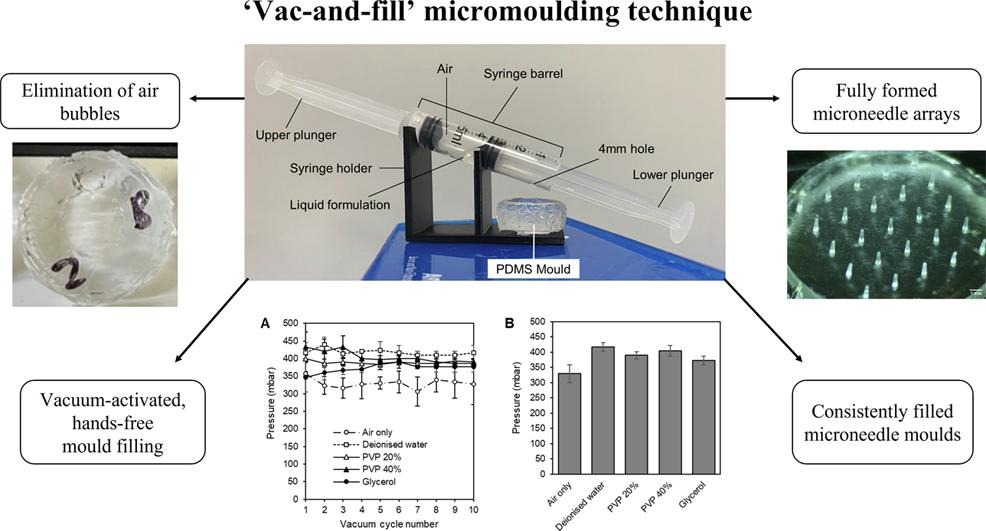

Our latest paper, Vac-and-fill: A micromoulding technique for fabricating microneedle arrays with vacuum-activated, hands-free mould-filling, has been published in the International Journal of Pharmaceutics. It’s open access, so head over there to read the full-text article for free!

This paper reports the solution to a problem that took us several months to solve. We were trying to mould a microneedle array patch. There are basically two ways to do it: you fill the mould with the liquid formulation and either centrifuge it or degas it under vacuum. Both techniques are widely reported in the literature. They have been designed to force any air out of the microcavities in the mould, so that the formulation can enter them to form the microneedles. We didn’t have the right rotor to go with the centrifuge, so we opted for the vacuum degassing technique, fully expecting it to be a walk in the park. What a disappointment that turned out to be! We discovered that our formulation was too viscous to allow the air to escape. We ended up with a lot of air bubbles trapped in the liquid formulation.

We quickly realised that the vacuum degassing technique reported in the literature had used low polymer concentrations, which meant that their liquid formulations were not as viscous as ours. To micromould the microneedle array patch successfully from our viscous formulation, we had to remove the air first before filling the formulation into the mould. But how would one fill the mould under vacuum?

The answer: a modified syringe, a 3D-printed part, some painstaking calibration, and viola! The paper describes our solution in full, but here’s a peek of the contraption in action.

This is Emma’s first paper and our first together with Dr Katarina Novakovic‘s group. Congratulations, Emma, and thank you team for the hard work!