Ever wondered what goes on in the Newcastle University Biomedical Sciences labs behind the scenes? On Wednesday 28th February, researchers from the school of Biosciences, Nutritional and Sports Sciences organised a Microbiology research fair to give students a sneak peak into the fascinating world of microbiology research, PhDs, careers, summer placements and final year projects. There were also amazing opportunities to go and see the research laboratories and facilities on the lab tours. So I couldn’t resist tagging along to see what was going on – and let me tell you, it didn’t disappoint! From chatting with researchers deep in ground-breaking projects to getting a first hand look at cutting-edge equipment, there was so much to discover.

There were many areas of research, but one big topic that caught my attention was the gut microbiome. Even though this research fair was mainly aimed at Biosciences students, it was interesting as a student dietitian myself to see the vast amount of research that the University is conducting on this area, as it is a really new and exciting area in the advancing field of nutrition. Some PhD students were researching into how fibre is broken down in the gut by different strains of gut bacteria and how the body uses these chemicals that are produced. One student was focussing particularly on how caramelised sugars are digested by the gut microbiome, and even though excess sugars are seen to have harmful effects on health, some gut bacteria can break these down to useful chemicals!

One of the most interesting stations for me was the station that was showing a machine taking species from the sea to make antibiotics. A remote machine goes down 4000m deep in the South Pacific and takes samples from the bottom of the ocean. It was fascinating how intricate the collection process was, yet how simply the machine could extract the sediment. These samples are then transported back to the labs and the microbes are cultured. The microbes of particular interest to them are Actinomycetes, and these produce 70% of all antibiotics. These actinomycetes have the ability to kill MRSA and other large strains of microbes. These researchers really had a passion for the undiscovered potential of the sea, and it seems like this is a really up and coming area of research.

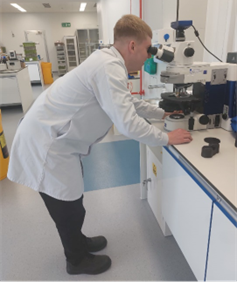

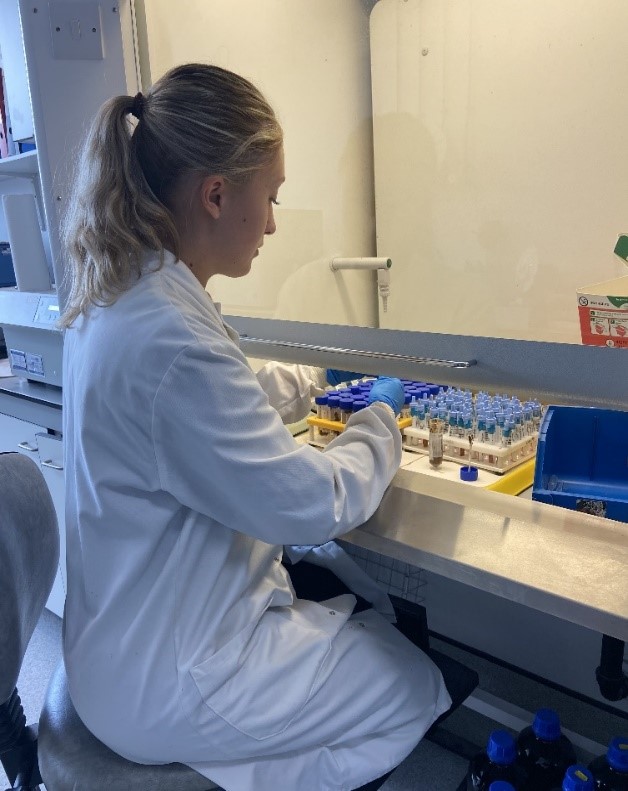

The most exciting part of the afternoon was the tours of the research labs! From state-of-the-art equipment to cutting-edge facilities, the students got a first hand look at what goes on in the world of research. Our tour leader’s research was focussing on Staphylococcus Aureus. Yes, we are talking about the superbug MRSA – a bacteria that is very complicated as it has the potential to cause lots of different diseases.

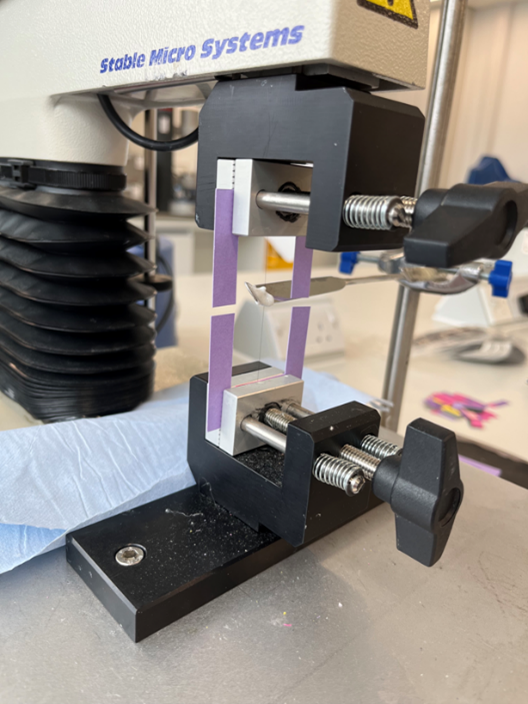

The labs had loads of cool equipment – the second one we were showed around was a biochemistry lab with research focussing on proteins. Their mission is to purify tiny proteins to find the protein of interest, and then grow crystals of it. The coolest machine in the lab by far was the X ray generator, which focuses on the protein crystal. The x ray signal is then amplified and detracts using electron density, which will rotate and shoot as many x rays as possible to collect the data. This helps them to calculate the structure of the molecule with the help of computer software, therefore figuring out what the protein looks like and its function. Ever heard of the lock and key interaction? Well, imagine the protein as the lock and the target molecule as the key. With 3D printing technology, these researchers can create super cool models of the protein structure. And here’s a fun fact to wrap things up – this model below was created of a tyrosine residue. Turns out, it’s not just some fancy scientific term – it’s actually a super important ingredient that can be used in toothpaste to break down plaque in your mouth, showing how important this science research is in everyday life!

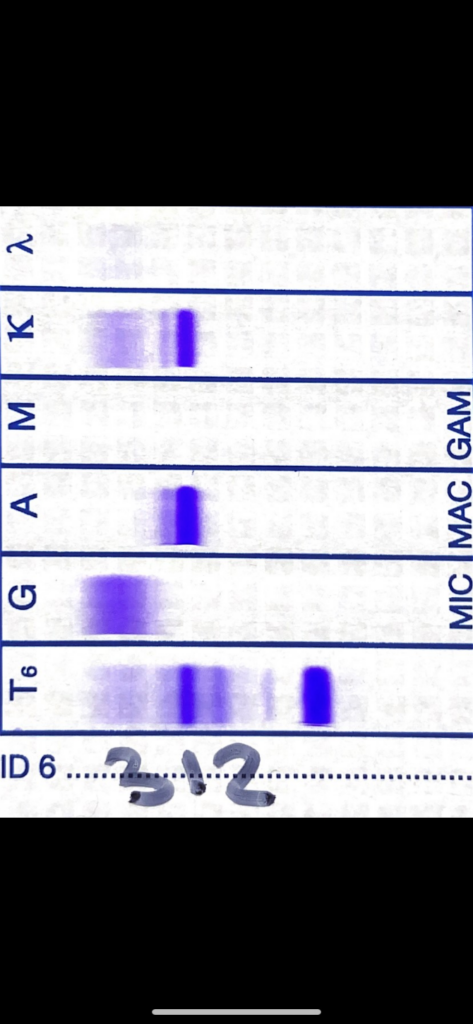

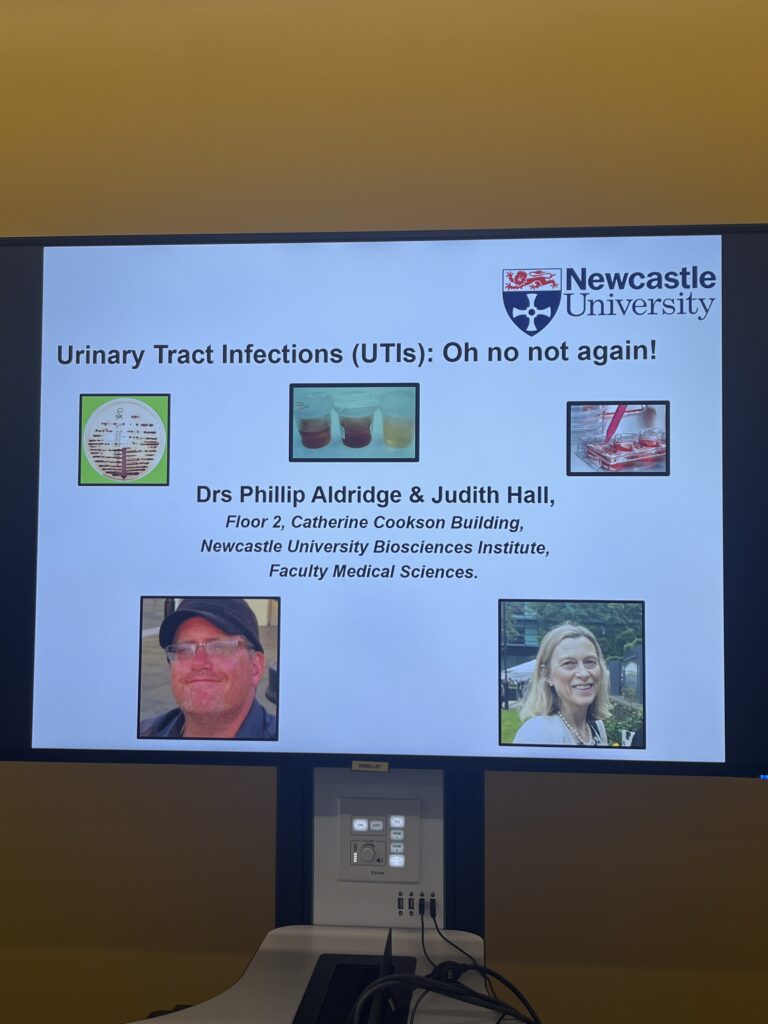

Biomedical scientists are also actively involved at the Freeman Hospital in researching urinary tract infections (UTIs) through a patient-centred approach, involving collaboration with clinicians ant their patients. This approach emphasizes the importance of understanding the individual needs and experiences of patients in managing and treating UTIs. By working closely with clinicians and patients, these biomedical scientists are contributing to the development of personalized treatment strategies and interventions to improve patients outcomes. They also are conducting laboratory based research to better understand the underlying causes of UTIs, including identification of pathogens, antibiotic resistance patterns and host immune responses to help advance our understanding of them and develop more effective treatment options. This work shows the diverse scope of the Biomedical science profession, which extends beyond traditional lab-based research to the hospitals to use more patient-centred approaches to better improve quality of care.

The research showcased at the fair provided a glimpse into the groundbreaking research happenign at the university in various fields. From the gut microbiome to exploring the potential of the sea for antibiotic discovery, students had so much opportunity to ask questions. The future of science is definitely looking bright!