By Sam Branton, Stage 3 Pharmacology

Hi, I’m Sam, I completed a placement year as part of my BSc Pharmacology degree. I worked as an analyst for Almac Group for 14 months at their Charnwood Site (in Loughborough).

Almac Group is a Northern Irish pharmaceutical contract development and manufacturing organisation (CDMO). Pharma Services was the part of the company I worked for, specifically the Analytical Operations department.

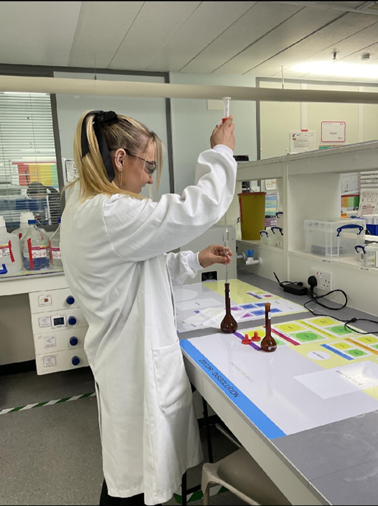

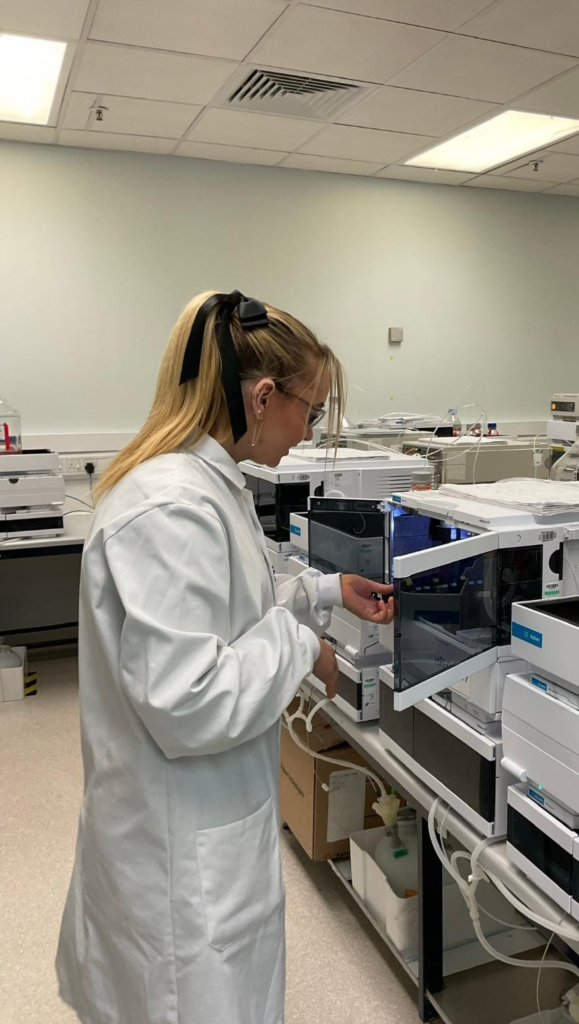

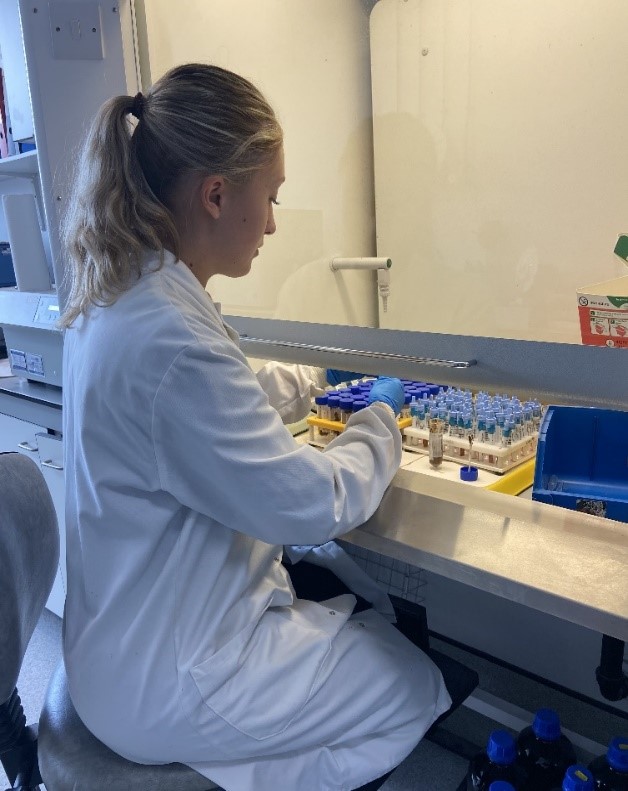

As an analyst I was responsible for performing the analytical testing of drug products and drug substances. The lab I worked in was a Good Manufacturing Practice (GMP) compliant lab so there were procedures to follow for pretty much everything that I did. This was tricky to begin with, but once I got used to it, it became a lot easier.

A day in the life of an analyst

Working for a CDMO meant that I got to work with many different companies’ products. I worked with many different drug products and performed many different types of analytical tests. Unfortunately, due to the products I worked on being in the early phases of clinical trials, there was a lot of confidentiality around the companies I worked with and the products I analysed.

Volumetric flasks – a regular sight on placement. Photo by Mikhail Nilov on Pexels.

There was a lot of training I had to complete before I was able to perform any analysis. This involved reading and being signed off on all standard operating procedures (these basically told you how everything was done) related to the task. This took a very long time due to the amount that there were, so the first few weeks were not the most exciting. It got much better when I started my practical assessments for the analytical techniques. Then I could complete analysis on products.

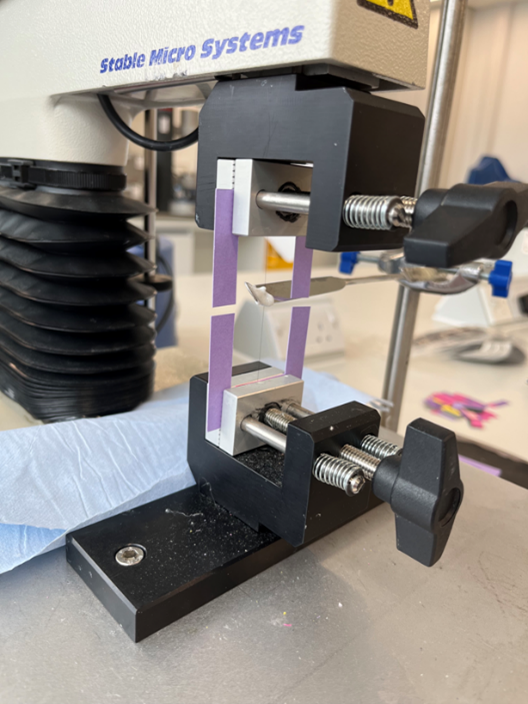

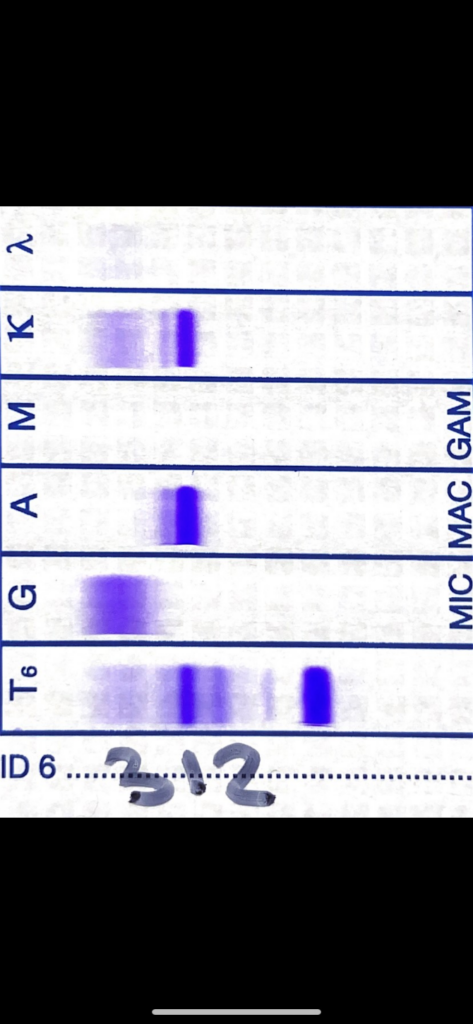

I was trained in a range of analytical techniques; dissolution, content uniformity, assay and related substance, water content (Karl Fischer titration), water activity, appearance, hardness, and disintegration. Some of which had to be analysed by high-performance liquid chromatography (HPLC) (or ultra-performance liquid chromatography (UPLC)) or UV-Vis spectroscopy, all of which I had to be trained on. Over the year I managed to gain lots of experience with each of these analytical techniques.

Even though this was a chemistry-based role, placements provide training to ensure you are confident in your role. So, if you are thinking about applying to a role that isn’t directly linked to your degree I’d still recommend applying!

Being a placement student

Despite being the only placement student on the site, I never felt out of place. Everyone was really friendly and made me feel welcome as soon as I started. As placement roles are usually similar to graduate roles, I worked with a lot of people who were also starting their first full-time job, which helped with my transition into the role.

Outside of my placement, every Thursday me and some of my colleagues would go to the local climbing centre to relax and catch up outside of work. This made my placement year so much more enjoyable and helped me discover a new hobby I really enjoy!

Discovering a new hobby in climbing – a good way to decompress after work! Photo by cottonbro on Pexels.

Do I recommend doing a placement year?

Definitely! I learnt so much during my placement and learnt how to use many bits of fancy (and expensive) equipment that I wouldn’t have done if I’d gone straight into my final year. Pretty much all placements are paid too which can help reduce some stress for your final year. The experience you gain from your placement will help when applying to graduate roles. It’s also possible to be offered a job where you completed your placement for when you have finished your degree! So, if you are considering applying, I’d highly recommend it!

If you’re applying to placements, good luck! Photo by Jon Tyson on Unsplash.