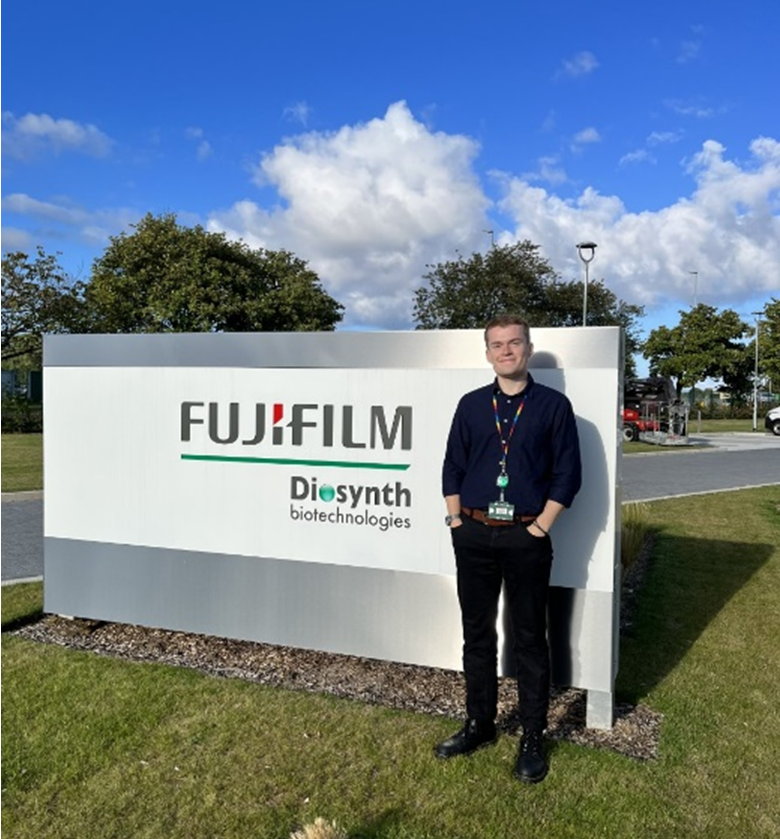

By Declan Wales

FUJIFILM Diosynth Biotechnologies (FDB for short) is a global contract development and manufacturing organisation (CDMO) in the biopharmaceutical industry providing process development and manufacturing of biologics, cell and gene therapies and viral vaccines. This basically means that FDB are able to manufacture a broad range of therapeutic proteins for customers using mammalian, bacterial, viral and insect expression systems and can develop these expression systems to suit the needs of these target compounds.

I spent my placement year within the Process Development (PD) division, specifically the Mammalian Cell Culture (MCC) PD department. One of the tasks in my department was to carry out optimized fed-batch processes using bioreactors to grow cell lines, the cells then produce the target therapeutic protein which can then be purified and analysed by other departments within PD for customers.

Why did I want to do a placement?

When starting my degree I hadn’t thought about the possibility of doing a placement year. Then COVID hit and my degree was heavily impacted which meant I missed out on a lot of lab sessions and became disappointed with the lack of hands-on experience I was getting. I read the BNS placement blogs and was really impressed with what other students had got up to in previous years and how they were able to get some industry experience before graduating so I applied for three placements that appealed to me and managed to secure the second one which was FUJIFILM Diosynth Biotechnologies!

A Day in the life

I’ve found every day to be different so there wasn’t much of a typical day. However, we had a team meeting daily to discuss everyone’s tasks for the day which gave me the opportunity to offer my help and get involved in work.

A typical bioreactor used at FDB: Art used from FDB marketing

Sampling an XDR10 Bioreactor for daily analysis

If there was a bioreactor process ongoing, then my days would be much more regimented. The morning would begin with sampling several bioreactors growing Chinese Hamster Ovary (CHO) cells and measuring the metabolites, gases, osmolality and cell counts using high-tech analytical equipment. Sampling shows us how the culture is doing and if we need to alter any of the parameters to improve the process, any abnormal data would indicate possible contaminations which are serious during customer projects. These bioreactors would need feeding later in the day with supplements such as feeds, glutamine and glucose to maintain the cultures and ensure the best product titres.

Adapting to a new routine

I thought I would be able to adapt quickly to working on placement, but it was harder than I anticipated. The 9 to 5 is a big change when you are used to the flexible timetable of university and it can be hard to stay engaged at work if you are tired so making sure you get enough sleep is important. However, one huge benefit was that my weekends were totally free and I could do whatever I liked free of Uni work. I had a lot of training to ensure I was confident and competent in carrying out my tasks which can take some time to get used to and can be a lot of information to take in but it meant that I was comfortable undertaking tasks independently.

It’s not all lab work!

I found time outside of the lab to be just as fulfilling as time in the lab. I had not really thought before about the business side of science but it was interesting to see the relationships between employees and customers when I attended meetings for certain projects and how being able to present information and communicate effectively and professionally with customers is just as essential in an industry role as is being skilled in the lab.

I got to take on responsibilities outside of the lab that were essential to the running of my department, the biggest helping to implement a new electronic laboratory notebook system in which I inputted equipment as well as essential reagents used for media and feed preparations. I also got to train my colleagues how to use this system and software for their feed preps as I was the one of the first to use it. This allowed me to develop important skills outside of the lab which I can now demonstrate to future employers.

Would I recommend a placement?

Yes, I would absolutely recommend a placement for a lot of reasons, some of the main ones being:

- You get more lab experience if you’re on a lab-based placement

- You gain a lot of new skills you can demonstrate in the future and develop ones you already have

- You can earn a good wage

- You get to experience the science industry and see if it’s for you

- Make friends/network with people in the industry find out what they did and if they enjoy what they do

- In some cases, if you impress the company they will offer you a job if you come back after you have graduated