Amelia Pettitt tells us how she balances her Chemical Engineering degree with competitive running, hobbies and part time work.

I’m currently in my fourth year of study of Chemical Engineering, specialising in sustainable engineering to complete my masters degree. I am also a highly competitive runner and therefore when I first came to university I was unsure of how I would manage the work/life balance of studying an intense degree like engineering with my sporting commitments. However I soon realised that although this would be a challenge, my involvement in both would complement each other.

In stage 1 the typical contact hours were 9-1 each day, which I found worked really well for me. As the course requirements weren’t too intense, I enjoyed going to the gym at 1 after my lectures to give myself a break, before completing tutorials and any assignments later in the afternoon. I was catered therefore I had another break to go to dinner with my flatmates. I didn’t realise it then, but all these breaks were really benefiting my studies and I felt I was constantly socialising!

Being surrounded by other students in halls with less contact hours didn’t phase me and I didn’t feel I missed out. If I wanted to go out, I could often manage one night a week, which I found was enough for me. I would always choose the sport night on a Wednesday as this allowed me to see my running friends as well as my flatmates. My flatmates would often go out more than this, but my halls were so big that there were other chemical engineers nearby that wouldn’t be going out, and there is something quite satisfying about seeing them hungover and missing out on a free breakfast when you wake up feeling fine.

Being surrounded by other students in halls with less contact hours didn’t phase me and I didn’t feel I missed out. If I wanted to go out, I could often manage one night a week, which I found was enough for me. I would always choose the sport night on a Wednesday as this allowed me to see my running friends as well as my flatmates. My flatmates would often go out more than this, but my halls were so big that there were other chemical engineers nearby that wouldn’t be going out, and there is something quite satisfying about seeing them hungover and missing out on a free breakfast when you wake up feeling fine.

In stage 2 the contact hours increased slightly, but the days were more spread out with lectures spanning the day 9-5 with multiple breaks. From stage 2 onwards I began to work in uni 9-5 and complete my training and gym sessions outside of this. I found this worked really well for me, as I could switch my brain off and socialise with friends not on the course after a full day in university. I found I had less time to go out, but this was mainly because of my training commitments rather than the course. I became more disciplined and structured with my time, and this provided me with a healthy lifestyle. I also applied for a placement year for after second year. I found I spent a lot of time preparing for interviews with help from the careers service. The course was structured to enable this, with majority of the weighting of the year based on January and June exams rather than assignments, giving me time before Christmas to secure my placement. I still worked at weekends if I needed to, however this probably wasn’t essential – definitely if you aren’t applying for placements and training once or twice each day!

After my placement year I found the 9-5 routine was ingrained in me and I wasn’t looking to change it coming back to university! It is difficult to have every weekend off, as things do come up in the week and I always want to try to make up for this lost time. However overall, now in my last year of study, I tend to take weekends off. I’m either travelling to races or exploring Newcastle – making the most of my last year in the city.

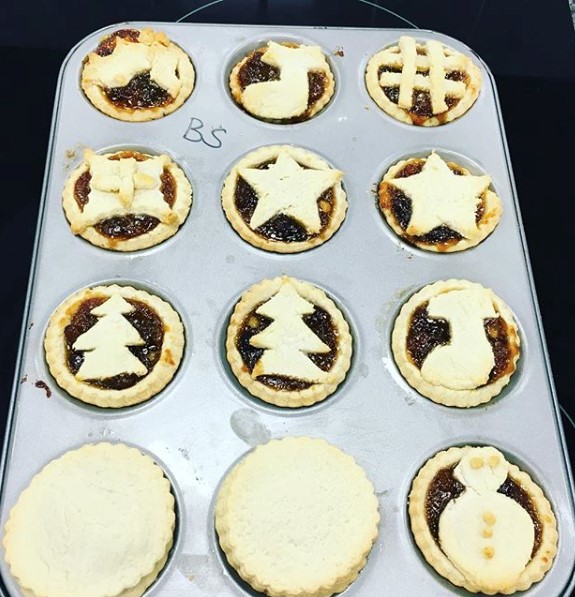

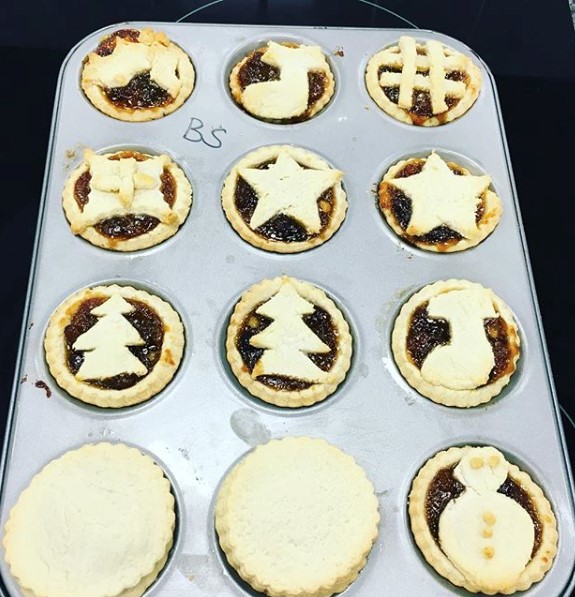

I’m also part of the baking society. I enjoy baking as its almost like engineering in the way you have to plan in advance and follow a schedule to ensure your bake will be successful. However I also find it very relaxing and a chance to be away from the computer for a little while. I bake on the university campus which is ideal – the society provide all the equipment and ingredients and I just bake for a couple of hours and head back to the library with my fresh library snacks. It’s perfect, and doesn’t take up too much time out of my day. I find adding hobbies into my day at specific times really helps my studies as I am more motivated to work hard if I know I need to leave at a set time.

Engineering has a lot of contact hours, which although this may lead people to believe it would be less social, it actually results in having a lot more friends! I know everyone in my year at university and I live with Chemical Engineers. This is ideal for asking for help and feeling at home at university. If I need help, I can always find someone in the computer cluster. I have other friends too, from the university triathlon team, cross country team and baking society, all of which hold social events for when I do want a break from any chemical engineering talk. I’ve been to Edinburgh, Sheffield, Stirling, Brighton, Manchester, Leeds, and London – all over the UK with the teams competing.

If you are worried about the financial side of university, Engineering opens doors to many scholarships which are definitely worth working towards! If you feel you need a part-time job, then there are many opportunities on campus including those to be a student ambassdor and street scientist. As a student ambassador I show future students around the university. As a street scientist I perform simple science experiments to explain everyday concepts to children aged primary school to A level, on campus and at local schools and events. I thoroughly enjoy them both, and they add to my communication and presentation skills, as well as my scientific knowledge!

If I was to choose to come to university again, despite how challenging chemical engineering can be at times, I don’t believe there is a better degree to do. Chemical engineering gives you so many transferable skills, providing a technical background and supportive learning environment. There are so many opportunities to get involved in through extra activities on offer at university, and with an engineering degree, you can still fit these in by prioritising the most important which is an essential skill to set you up for the working environment.

Find out more about Newcastle University’s Chemical Engineering courses here.

Being surrounded by other students in halls with less contact hours didn’t phase me and I didn’t feel I missed out. If I wanted to go out, I could often manage one night a week, which I found was enough for me. I would always choose the sport night on a Wednesday as this allowed me to see my running friends as well as my flatmates. My flatmates would often go out more than this, but my halls were so big that there were other chemical engineers nearby that wouldn’t be going out, and there is something quite satisfying about seeing them hungover and missing out on a free breakfast when you wake up feeling fine.

Being surrounded by other students in halls with less contact hours didn’t phase me and I didn’t feel I missed out. If I wanted to go out, I could often manage one night a week, which I found was enough for me. I would always choose the sport night on a Wednesday as this allowed me to see my running friends as well as my flatmates. My flatmates would often go out more than this, but my halls were so big that there were other chemical engineers nearby that wouldn’t be going out, and there is something quite satisfying about seeing them hungover and missing out on a free breakfast when you wake up feeling fine.